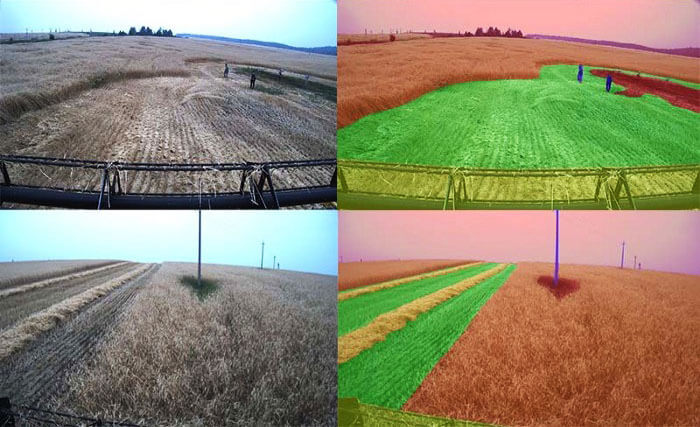

Drones have come to our lives in many aspects. However, their energy consumption and autonomy are still an issue to be dealt with in order to be applicable in more fields of interest.

As in the past that many discoveries and inventions mimic nature, so a team of researchers at the Swiss Federal Institute of Technology Lausanne, led by Enrico Ajanic, have built a 284-gram drone with a maximum wingspan of 1.05 metres inspired by the northern goshawk (Accipiter gentilis).

Ajanic contended that both multicopter drones and winged drones have an innate flaw. The first ones can hover and move well, but can’t fly long distances, whereas the latter can fly long distances, but aren’t very agile. He claimed that the robo-hawk brings the benefits of different unmanned aerial vehicles into a single unit.

“These results shed light on the avian use of wings and tails and offer an alternative design principle for drones with adaptive flight capabilities,” wrote the authors in a paper for the journal Science Robotics.

The idea behind constructing this robo-hawk is imitating the flight behaviour of birds by equipping the robot with motors that allow its wings to fold in or out, and its tail to contract or to fan out. The robo-hawk spreads its wings and tail to gain height and then, upon reaching top speed, the wings and the tail are tucked in, thereby enhancing aerodynamics, imitating a real hawk flight.

“The morphing wing and tail structures of this design are insightful and novel,” said Jonathan Aitken at the University of Sheffield, UK, who was impressed by the robot’s ability to adjust its manoeuvrability mid-flight. “It offers the potential for unconventional flight manoeuvres, such as slow but controlled flight at high angles of attack”.

Ajanic aims to integrate artificial intelligence to increase the robot’s level of autonomy and rendering it capable to fly without human control or supervision.

Sources:

https://www.technology.org/2020/11/02/this-robot-hawk-can-fly-long-distances-and-uses-less-power/

https://www.newscientist.com/article/2258426-hawk-inspired-robot-with-movable-wings-is-an-agile-long-distance-flyer/

https://robotics.sciencemag.org/content/5/47/eabc2897

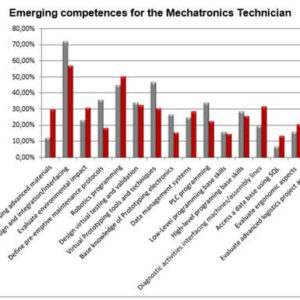

clearly demonstrates that, over the last few years, interest in mechatronics has been reinvigorated due to the advances in sensing, communication, and computing.

clearly demonstrates that, over the last few years, interest in mechatronics has been reinvigorated due to the advances in sensing, communication, and computing. and students’ point of view, the priority competencies that a technician in mechatronic should have to comply with the production system of the future are:

and students’ point of view, the priority competencies that a technician in mechatronic should have to comply with the production system of the future are: tried to compare and classify the different priorities of the Partner Countries regarding some statements about mechatronics discipline.

tried to compare and classify the different priorities of the Partner Countries regarding some statements about mechatronics discipline.

The first thing coming to our mind when talking about positive reinforcement is maybe dogs. Pavlov with his experiment with his homonymous dogs was o pioneer of behavioural psychology. Something more than a century later from Pavlov’s experiments Johns, Hopkins University computer scientists showed a robot how to teach itself several new tricks, including stacking blocks by using the method of positive reinforcement, an approach familiar to anyone who has used treats to change a dog’s behaviour. With this method, the robot, named Spot, was able to learn in days what typically takes a month.

The first thing coming to our mind when talking about positive reinforcement is maybe dogs. Pavlov with his experiment with his homonymous dogs was o pioneer of behavioural psychology. Something more than a century later from Pavlov’s experiments Johns, Hopkins University computer scientists showed a robot how to teach itself several new tricks, including stacking blocks by using the method of positive reinforcement, an approach familiar to anyone who has used treats to change a dog’s behaviour. With this method, the robot, named Spot, was able to learn in days what typically takes a month.

contributions of science is serving the humans’ needs. Disabilities make a person feel constrained and fully dependent to his closest people. However, French researchers at biomedical research centre Clinatec and the University of Grenoble claim that they had overcome this problem in a premature, still functional, approach.

contributions of science is serving the humans’ needs. Disabilities make a person feel constrained and fully dependent to his closest people. However, French researchers at biomedical research centre Clinatec and the University of Grenoble claim that they had overcome this problem in a premature, still functional, approach.

Danish company specializing in automation and production of cobots, training has particular importance.

Danish company specializing in automation and production of cobots, training has particular importance.

to identify an anomaly quickly is very important, because it allows to intervene promptly and, if necessary, to shut down the line, with obvious economic savings. Knowing how to do this depends on three factors: essential mechanical and electromechanical preparation; an in-depth practical experience; a systemic mentality aimed at methodically analysing phenomena and identifying the causes.

to identify an anomaly quickly is very important, because it allows to intervene promptly and, if necessary, to shut down the line, with obvious economic savings. Knowing how to do this depends on three factors: essential mechanical and electromechanical preparation; an in-depth practical experience; a systemic mentality aimed at methodically analysing phenomena and identifying the causes.