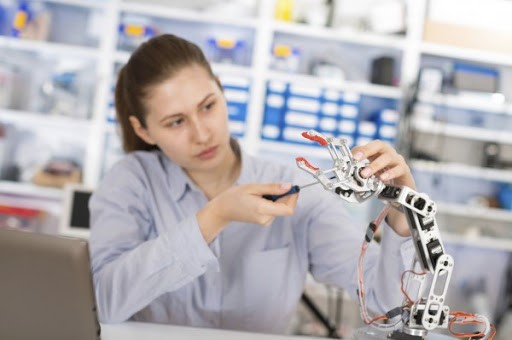

SecondHands is the robotic Horizon 2020 Research and Innovation project, with  the aim to design a robot that can offer help to a maintenance technician in a pro-active manner. The project researchers and developers see this robot as a second pair of hands that can assist the technician when he/she is in need of help. To operate within environments designed primarily for industrial efficiency, but centered around a human workforce, a robot should possess a rich repertoire of human-like skills, and probably a humanoid or human-like form, specifically in order to use the same methods of access.

the aim to design a robot that can offer help to a maintenance technician in a pro-active manner. The project researchers and developers see this robot as a second pair of hands that can assist the technician when he/she is in need of help. To operate within environments designed primarily for industrial efficiency, but centered around a human workforce, a robot should possess a rich repertoire of human-like skills, and probably a humanoid or human-like form, specifically in order to use the same methods of access.

The project revolves around four fundamental concepts:

- the design of a new robotic assistant;

- a knowledge base to facilitate proactive help;

- a high degree of human-robot interaction;

- advanced perception skills to function in a highly dynamic industrial environment.

SecondHands aimed to develop a robot assistant that is trained to understand maintenance tasks so that it can either pro-actively, or as a result of prompting, offer assistance to automation maintenance technicians performing routine and preventative maintenance. Conceptually the robot’s task is to provide a second pair of hands to the maintenance technician, such that once the robot has been trained, it can predict when it can usefully provide help and knows which actions to take to provide it.

In general, industrial automation is designed to incorporate as little flexibility as necessary to perform its core function – the basic concept of a production line. In an industrial environment, flexibility is traded for simplicity and repeatability in order to leverage efficiency. However, even these simple and efficient automated systems still require maintenance, as they cannot maintain themselves. The industrial sites that house these systems are often designed with only secondary consideration given to maintenance tasks and the necessary access by a human. There is usually no consideration of enabling an access to a robot.

The project was developed under the auspices of a consortium of researchers and computer scientists from a number of organizations, including Ecole Polytechnique Fédérale de Lausanne (EPFL); Karlsruhe Institute of Technology (KIT); Sapienza, University of Rome; University College London (UCL); and Ocado Technology, the technology division of the U.K.’s online-only grocery giant Ocado.

More project information on the Secon Hands project web site here https://secondhands.eu

Project Video Url on YouTube https://youtu.be/-KF5XSSTn_o

Second Hands YouTube Playlist https://secondhands.eu/index.php/gallery/

Slides summarizing the project objectives https://secondhands.eu/wp-content/uploads/2015/06/SecondHands_ERF_Vienna_2015_WithLogos.pdf

More showcases from the trials can be found here https://venturebeat.com/2020/05/05/eu-robotics-project-gives-maintenance-workers-a-second-pair-of-hands/

workers to review ways of collaborating with their companies, and managers are finding that, after an adaptation period, this could be confirmed in the long run.

workers to review ways of collaborating with their companies, and managers are finding that, after an adaptation period, this could be confirmed in the long run.