We asked some questions to all the actors involved in this experience (the company that joined the training project, the students, the teachers, Federmeccanica and the Stakeholders) to collect their direct point of view and draw some conclusions before the start of the second phase.

Company (Giuseppe Schiavone – Project Manager Ditro-Designa S.r.l.)

Having concluded the first part of the NEW METRO experiment, co-funded under the Erasmus program, what considerations do you feel you can share?

Ditro-Designia: we are glad to be an active player of the NEW METRO experiment, as we got the opportunity to significantly widen the core skills of our employees in a relevant topic for our business, leveraging on the experience and the competences offered through the project. Employees felt the effectiveness of the training, especially because were able to move from theory to practice in “real-time” mode.

Do you find it a valuable and replicable system for introducing innovative solutions for adult education?

Ditro-Designia: definitely yes, as it links theoretical notions (that can be delivered even remotely) with the opportunity to practice the lessons learned, so optimizing in this way the performance of the training. Considering even the pandemic situation, the organization resulted in a remarkable gain of competences, sincerely recognized by the students, too.

Students

You students have been involved in the whole process, from unboxing to learning how to use the Robot, passing through its programming, which phase was most useful for you? Was the remote teaching method effective? Do you agree to include these teaching and training methods in current programs, even after the pandemic?

Every single phase of the training represented a source of innovation and learning for us. Just to mention one, we can say that the setting phase of the robot was really interesting, as it was a sort of “official kick-off” of the training. We firmly believe this can represent a reference baseline for the training courses even after the pandemic period.

Training Manager (Sigfrido Pilone – Assocam Scuola Camerana Director)

After this NEW METRO experience and in the light of the global economic and employment framework that imposes physical restrictions on the provision of training, how valid do you think it is to use the WBL methodology online?

Work Based Learning is a real opportunity when the teacher supports the student in a structured way and when the training is clear with respect to topics/content and above all clear, defined and measurable objectives.

In order to better explain the reasons for this answer, it is useful to contextualize it with the experience of Scuola Camerana, which organized the course.

In fact, Scuola Camerana has over 60 years of experience in technical and technological training and the Work Based Learning model has always been one of the reference models for training (even if not yet structured as it is today). Training delivered under task conditions to effectively simulate a work environment has always been an element of strength and motivation for the students of our institution.

The drastic limitations imposed by COVID, both in terms of travel and space sharing, have made it necessary to use technologies designed specifically for distance learning, supplemented by materials and equipment complete with technical kits distributed to learners to allow them to carry out practical exercises in distance mode.

In the case of NEW METRO, we use a robot that has been delivered to the company being trained and that is programmed by the trainees on the basis of the teacher’s instructions, who can also interact remotely with the robot itself, in remote control.

In addition, the recording of the lessons allows reviewing and deepening any topics independently and asynchronously by the trainees.

Particular efforts have been necessary for the training of the teacher who had to learn to interact with the students based only on the tone of voice and images of the webcams, which is not easy for everyone.

In conclusion, the WBL, integrated with online tools, is a mode that, with proper attention, can continue to be a valuable training tool.

Lecturer (Alessio Salmin – Technical Sw programmer Robot)

I certainly believe that the WBL model is a very good solution. With the right instruments and an effective organisation, we have seen that distance learning can be just as good as face-to-face training.

Federmeccanica (Sabrina De Santis – Education & Training Director)

After the experimentation experience made with the company Ditro srl and Designia srl, to which entities (for example, ITS and Enterprises) does Federmeccanica intend to propose new experimentation sessions relating to the NEW METRO project?

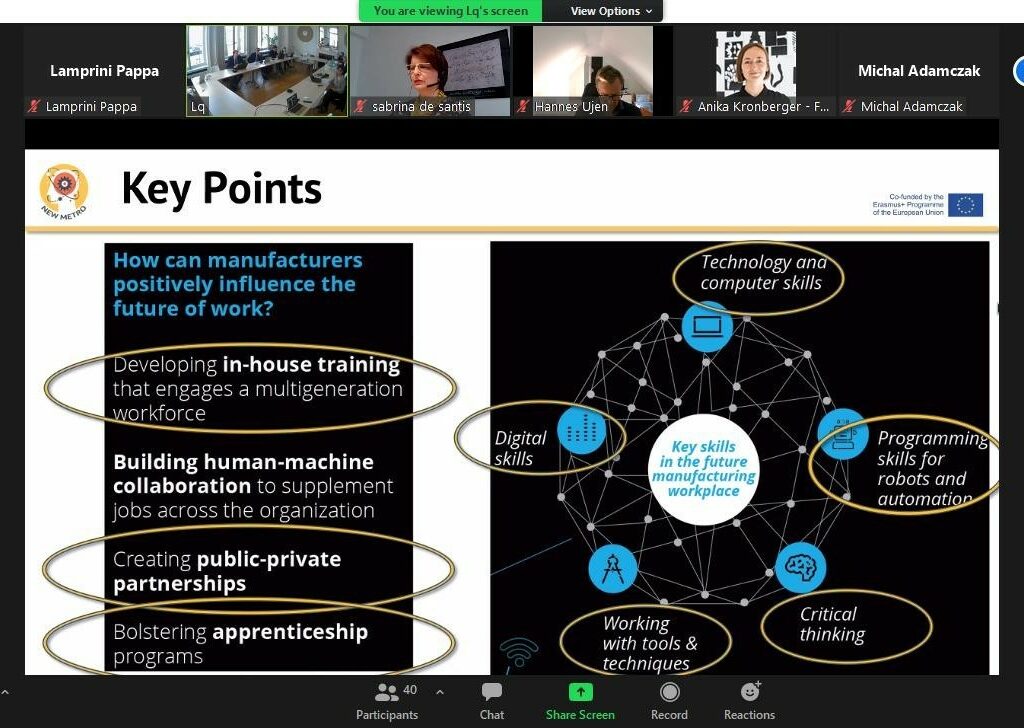

Federmeccanica is convinced that learning on the job is essential and fundamental for the development of skills. Join the NEW METRO partnership also responds to this mission: promote collaboration between schools and businesses. Taking part in the definition of a European CV of mechatronic skills and testing it through new forms of teaching, seemed an appropriate challenge.

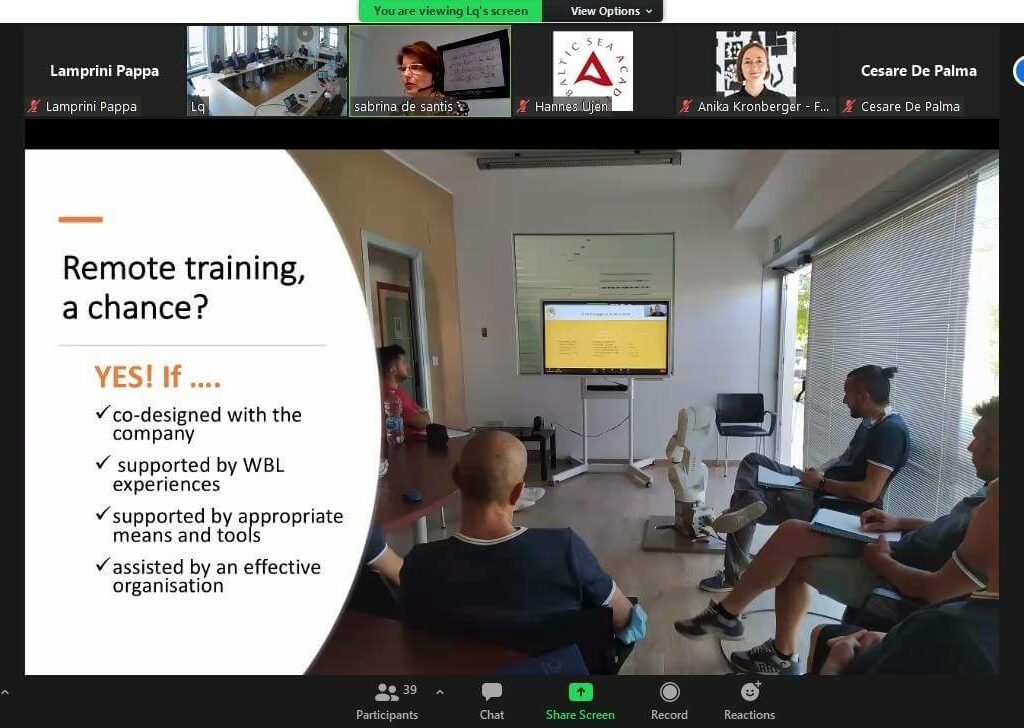

The piloting phase carried out showed us that a serious distance learning could be effective in developing technical skills, if it is co-designed with the company and supported by WBL experiences. The co-design of programs between company and trainer remains the fundamental basis. Indeed, it has been a phase on which we have worked extensively to achieve a good result.

We will certainly disseminate this experience to our whole system: the results achieved with the first phase of experimentation are encouraging and show how much we have to intensify our efforts for the highest quality and effectiveness of training, in order to foster the development of professionalism with skills responding to the ongoing labor market transformation.

Stakeholder (Cesare De Palma – President of the Mechanical, Electrical and Electronics Section of Confindustria Bari Bat)

NEW METRO is based on the philosophy of integrating the voices of the players involved in training for Mechatronics, bringing closer the need for updating expressed by the industrial sector, the training needs of workers and trainers. What actions will allow stakeholders to continue their involvement in updating skills and replicating the NEW METRO model (for example, by transmitting the NEW METRO offer to ITS, in the Fondimpresa catalogues, etc.)?

I believe that the New Metro project deserves a very broad replicability approach. It is not a project with technical content limited to a technology or a specific innovation. It has very broad implications that can involve different company levels: from designers to process or department managers, from supervisors to technical programming specialists. In our opinion, therefore, in addition to ITS, we need to think about school modules – through alternating school-work paths (PCTO) – and university professionalizing modules through which provide this type of training.

Regarding continuous training, collaboration with companies will be fundamental. It should be included in the catalogues of training courses offered by accredited bodies and should refer to calls for proposals linked to interprofessional funds.

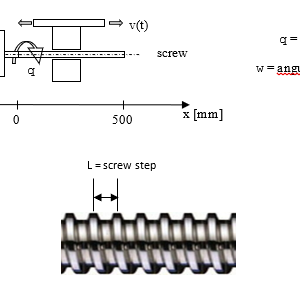

Last February, NEW METRO launched an international challenge to stimulate students in solving an operational project with a participatory approach. The challenge was undertaken by transnational teams of 5 to 10 students who cooperated together through virtual meeting, and practical work. Teams, hade up to 4 weeks to design a controlled linear system, by applying, amogst others mechanics and electronics engineering skills, together with the correct use of engineering software and IoT tools.

Last February, NEW METRO launched an international challenge to stimulate students in solving an operational project with a participatory approach. The challenge was undertaken by transnational teams of 5 to 10 students who cooperated together through virtual meeting, and practical work. Teams, hade up to 4 weeks to design a controlled linear system, by applying, amogst others mechanics and electronics engineering skills, together with the correct use of engineering software and IoT tools. Three teams of challengers competed with students and colleagues from countries participating in the NEW METRO project work with equal opportunities. The international teams, made by students of ITS Meccatronico Lazio (Rome), Institut de Vic and Institut Alt Penedès (Barcelona), University of Ioannina, and ITS MAKER (Reggio Emilia) developed original and different solutions to the same problem.

Three teams of challengers competed with students and colleagues from countries participating in the NEW METRO project work with equal opportunities. The international teams, made by students of ITS Meccatronico Lazio (Rome), Institut de Vic and Institut Alt Penedès (Barcelona), University of Ioannina, and ITS MAKER (Reggio Emilia) developed original and different solutions to the same problem.