The story, all Italian, told by the BBC (here the article) is exciting.

A hospital in Brescia (north of Italy) had 250 patients with coronavirus in intensive care, and its valve supplier was unable to produce all the valves necessary to cover the need. When an Italian journalist realized this, she put the hospital in contact with the General Manager of Isinnova, a 3D printer company. They went to the hospital for a quick visit and, three hours later, they had produced and tested a 3D printed prototype on a patient.

The result? One hundred respiratory valves printed in 24 hours.

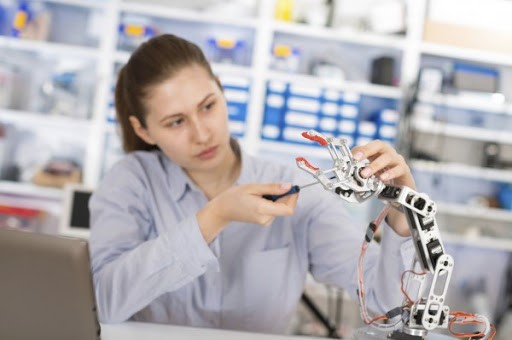

Isinnova has also joined forces with another local 3D printer company to meet demand. These companies are working for free, and the operators have been working non-stop for days but with a single thought: to help save lives, and mechatronics is at the basis of such technology and production capabilities.

Source: https://bbc.in/2KExDVN

in support of this learning module at the Rezekne Academy of Technologies has been extremely useful. It highlighted:

in support of this learning module at the Rezekne Academy of Technologies has been extremely useful. It highlighted: